The above benefits of industrial Ethernet cameras have made them indispensable for today's manufacturing, automation, and surveillance systems. The key benefits it offers are timely data transfer. Ethernet cameras are based on Gigabit Ethernet (GigE) technology, providing transmission speeds of 1,000 megabits per second (Mbps) which makes them well-suited for demanding applications that require real-time processing such as machine vision or in-line industrial inspectionistry. On the other hand, this high-bandwidth allows for transmission of high resolution images up to 12 MP (and even over), and ensures minimum lag times that are necessary in order to catch defects on fast industrial lines.

Long-distance transmission is another key benefit. GigE Ethernet Cables: Unlike other interfaces such as USB or FireWire, GigE ethernet cable can carry data over longer distances without requiring repeaters or hubs (distance limit = 100 meters). This function is useful especially in the case of large factories or workshops as cameras are in many cases located far from the control room. An example of this is an era manufacturer that used Ethernet cameras to institute productivity monitoring along the full length of its assembly line, which resulted in 30% shorter downtime because the cameras deliver their data digitized and are able to be placed more flexibly at a distance from one another.

Another benefit to these cameras is PoE (Power over Ethernet) With PoE, a single Ethernet cable can power and deliver data to the camera thereby reducing wire requirements. Easy to install, cost-effective and increases system reliability by reducing a bunch of cables. By accelerating application of labour, which is essential in sectors like wearing down combustion engines or logistics/heavy process manufacturing, PoE Cameras bring efficiency to the installation setup saving 25%time.

Industrial Ethernet Cameras — The scalability is another big advantage of these cameras. Ethernet networks are capable of multiple cameras on the same network, offering a simple way to scale systems as production needs change. Ethernet cameras allow for a modular solution in industries with, let's say, potentially hundreds of inspection points (as would be the case in food processing or electronics) where this elastic rollout can eliminate having to redesign the entire system. A 2022 study reported that companies relying on Ethernet-based camera systems had the costs to integrate their system cut by a healthy 15% (compared to those using an old-school, traditional analog).

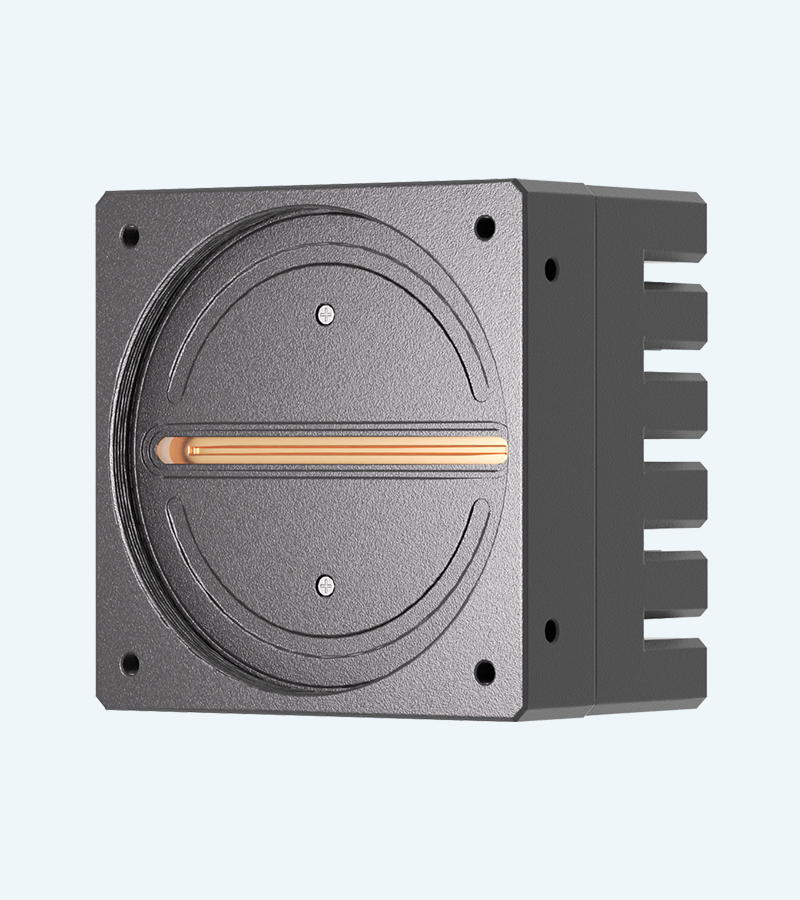

Another big advantage is the quality of images. These sensors are often provided with high-resolution support, ranking up to 20 MP and beyond for industrial Ethernet camera. At this level of resolution, the camera could be used in applications like 3D pattern recognition monthly calibration and photogrammetry machine tending optical flashing semiconductor manufacturing precision inspection where tiny defects can substantially affect product quality. The camera has been designed to see and picture at fast frame rates, sometimes 60 frames per second or more, allowing even quick objects to be operationally imaged with out introducing mistakes into an automated course of.

As Elon musk rightly mentioned, “The key of scaling is automation and precision”; industrial Ethernet cameras offer exactly the same; Precision (Accuracy), Speed and Scalability to automate more complex use cases in different industries.

Visit industrial ethernet camera for means and approach to implementing the benefits of an industrial how do people best address your organisations needs.